Introduction

Our parent company TOA Electric Industrial Co.,Ltd. was found Jun 1947 in Japan. We have first expanded overseas from September 1989, first location in Singapore.

Shin-A Precision Malaysia was found on March 2007, our name was changed to Artron Precision Malaysia on July 2019.

The Artron group business spread over 3000 products and global networks of 14 branches.

The Artron way

Realize Japan quality as a professional group of Monodzukuri

Drive new technology and pursue added value.

By putting the customer first and responding to difficult requests, we will grow ourselves.

Improve on-site capabilities by accumulating daily improvements with the participation of all

Achieve competitive costs by pursuing productivity

Understand the environment, laws and regulations, and comply with company regulations.

Follow safety rules and make a accident-free workplace.

Our customers are in areas

Automotive

Medical

Smart phone and tablet

Manufacturing

Semiconductor

Consumer Electronics

Thermal Solution

The Artron gurantee

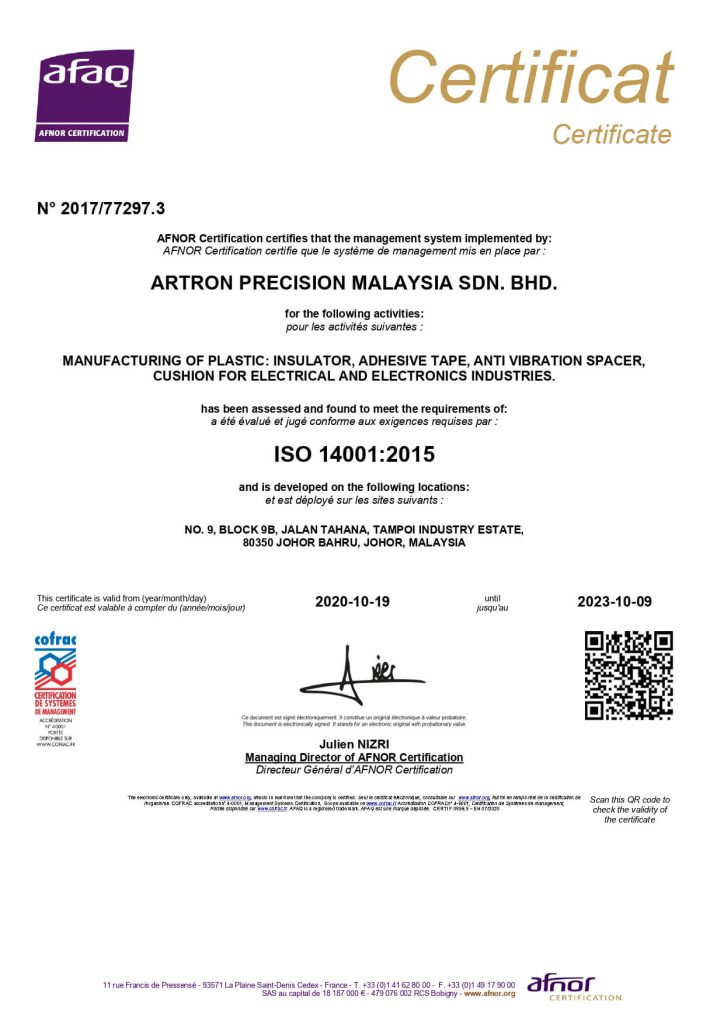

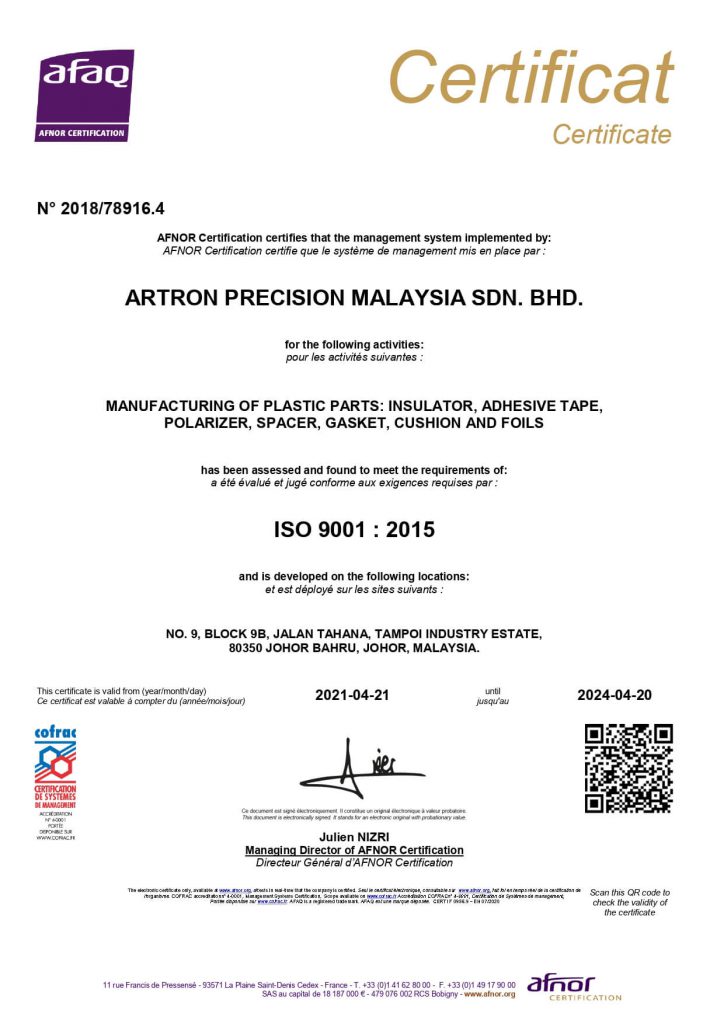

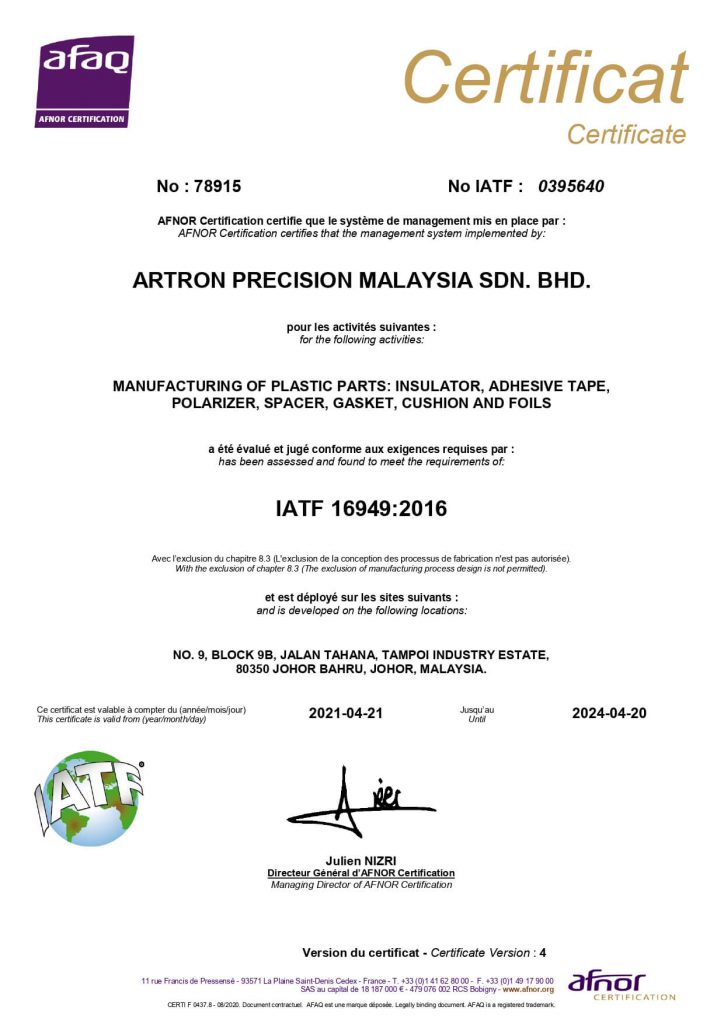

Our Factory is certified with ISO9001, IATF6949, ISO14001.

Adhering to quality policy, we are committed to exceed customer satisfaction through continual improvements.

We know that die-cutting accuracy is so important, we strictly manage our Productions, Operators, Supply Chains and Environment.

We ensure that all our products meet with customer’s environmental hazardous substances requirements.

We strive to achieve Zero Defect in our manufacturing and consistently meet customer’s expectation.

Technical Solution

We have the knowledge of how the materials perform in your equipment.

Complementing materials and equipment expertise is our ability to assist customers in understanding the production process and foster partnerships.

Tool & Die Localization

100% Tooling Localization.

We have ability to provide tooling design. (cost saving & lead-time improvement)

Sample Services

With our Laser Cutter and Super Cutter machines, we provide samples with free tooling & short lead time.

LMW

In order to keep competitiveness, our warehouse and manufacturing are on the same premise.Customs duty exemption for raw materials used directly in process from initial stage of production until finished product is finally packed ready for export.

Clean Room Facility

Class 10,000(ISO7)

Using a fully equipped Class 10,000 cleanroom, our manufacturing capabilities range from die-cutting and slitting to more-complex laser to produce intricate patterns and parts.

Multi-lingual Communication

English, Japanese, Mandarin, Malay

By maintaining open lines of communication, we are confident to support project runs and contribute to production and product improvements.

Value-added Job

From a full range of services, including tool designs, material selection, prototyping, component assembly, bending and packaging in controlled environments.

This arrangement simplifies the ordering process for customers to avoid having to contract out services to multiple vendors.